Food Processing & Frying Lines Accessories

Food Processing & Frying Machine Manufacturer & Supplier in Ahmedabad, India

At Gungunwala Food Equipment Pvt. Ltd., we understand that a successful snack production line requires more than just a fryer. It demands a fully integrated system where every stage—from preparation and forming to flavoring and oil management—is handled with precision and efficiency.

Our range of Food Processing & Frying Lines Accessories is engineered to seamlessly integrate with our Continuous and Multipurpose Batch Fryers, ensuring maximum throughput, consistent quality, and reduced manual intervention.

1. Raw Material Preparation, Slicing, and Snack Extrusion Machinery

The consistency and quality of your final product depend entirely on the precision of the initial preparation. Our equipment handles raw material processing and forming with industrial accuracy.

Potato Peeler

High-efficiency peeling for commercial potato chip lines, minimizing manual labor and raw material waste.

Potato Slicer

Delivers uniform slices, critical for achieving consistent thickness and even frying results.

Hydro for Potato Chips

A de-oiling/dewatering mechanism used post-frying to remove excess surface oil or moisture, crucial for achieving desired crispiness and a lower-oil product.

Banana Slicer

Specialized high-speed equipment for the precise slicing of banana chips in Banana Chips Production Line.

2. Post-Frying & Flavoring Systems

These ancillary systems define the final texture, taste, and packaging readiness of your finished snack.

Dough Mixer

Homogeneous mixing of ingredients for various products.

Namkeen Mixer

Dedicated solution for mixing namkeen (salty snack) dough ingredients.

Namkeen Extruder

Forms namkeen dough (sev, gathiya, etc.) into precise shapes before frying.

Kurkure Extruder

Essential for forming extruded snacks like Kurkure and specialized fryums.

Coating Pan

Used for controlled tumbling to apply an even coating of spices, sugar, or other flavorings.

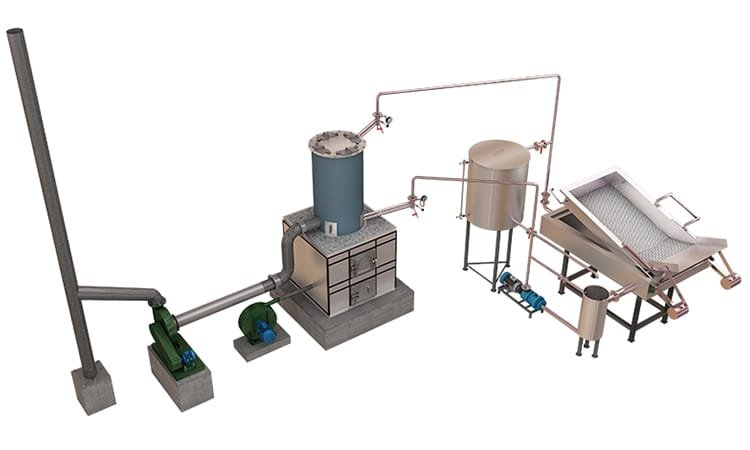

3. Oil, Heat, and Storage Management Solutions

Managing cooking oil purity and heat source efficiency is paramount to product quality and operating costs. Our dedicated solutions are built for performance and sustainability.

Oil Storage Tank

Industrial-grade stainless steel tanks for safe, large-scale oil storage. Capacities range from 5,000 Ltr. to 50,000 Ltr

Flavor Applicator & Drum

An automated system for the uniform and efficient application of dry seasoning (masala) onto snacks like chips and fryums.

Boondi Attachment

An accessory designed for seamless integration with namkeen fryers for the specialized production of Boondi (small fried snack drops).

Oil Filters

Essential components for continuous oil purification and the removal of fines, ensuring a longer oil lifespan and consistent product taste

Heat Exchangers

Components used to efficiently transfer heat from the burner or thermic fluid to the cooking oil.